Running a bustling commercial kitchen, whether it’s in a restaurant, a vibrant cafe, or a busy hotel, means countless dishes, glasses, and utensils pass through the wash station daily. It’s a non-stop cycle that demands not just efficient cleaning, but also effective drying. That’s where a top-notch Commercial Dish Drying Rack steps in, becoming an unsung hero in maintaining hygiene, optimizing workflow, and keeping your kitchen organized. It’s far more than just a place to set wet dishes; it’s a critical piece of equipment designed to meet the rigorous demands of a professional environment.

Why a Commercial Dish Drying Rack Isn’t Just “Any Rack”

Think about your kitchen at home – a simple rack on the counter does the trick, right? In a commercial setting, that just won’t cut it. The sheer volume and variety of items, coupled with stringent health and safety regulations, mean a commercial dish drying rack needs to be a robust, purpose-built solution. Its primary role is to promote rapid air circulation, preventing that dreaded “wet nesting” which can lead to bacterial growth and unsanitary conditions. It’s about ensuring every plate, pan, and piece of cutlery is thoroughly dry and ready for its next use, safeguarding both your customers’ health and your establishment’s reputation.

“A commercial kitchen is a high-stakes environment where every detail, even dish drying, impacts overall hygiene and operational efficiency,” says Chef Maria Rodriguez, a seasoned kitchen consultant. “The right rack drastically reduces drying time and minimizes contamination risks.”

Types of Commercial Dish Drying Racks: Finding Your Perfect Match

Just like no two commercial kitchens are identical, neither are their drying needs. Manufacturers offer a diverse range of commercial dish drying rack options, each designed to tackle specific challenges and fit various layouts.

Mobile Drying Racks: Flexibility on Wheels

Imagine the ease of moving your drying station wherever it’s most needed. Mobile commercial dish drying racks, equipped with sturdy casters, offer incredible flexibility. They can be rolled from the dishwashing area to a storage zone, or even temporarily positioned closer to a prep station during peak hours. This adaptability makes them ideal for kitchens that require dynamic space management or for catering businesses that need to transport clean wares. Many come with lockable wheels to ensure stability once in place.

Stationary and Wall-Mounted Racks: Fixed Solutions for Optimized Space

For kitchens with a consistent workflow or limited floor space, stationary or wall-mounted commercial dish drying racks are excellent choices. Stationary racks provide a permanent, heavy-duty drying solution, often integrated into a larger dishwashing setup. Wall-mounted options are brilliant for maximizing vertical space, keeping counters clear and creating an ergonomic drying area for frequently used items. They can be incredibly robust, often featuring heavy-duty steel or polymer construction to hold substantial weight.

Specialty Racks: For Glassware, Trays, Pots, and Pans

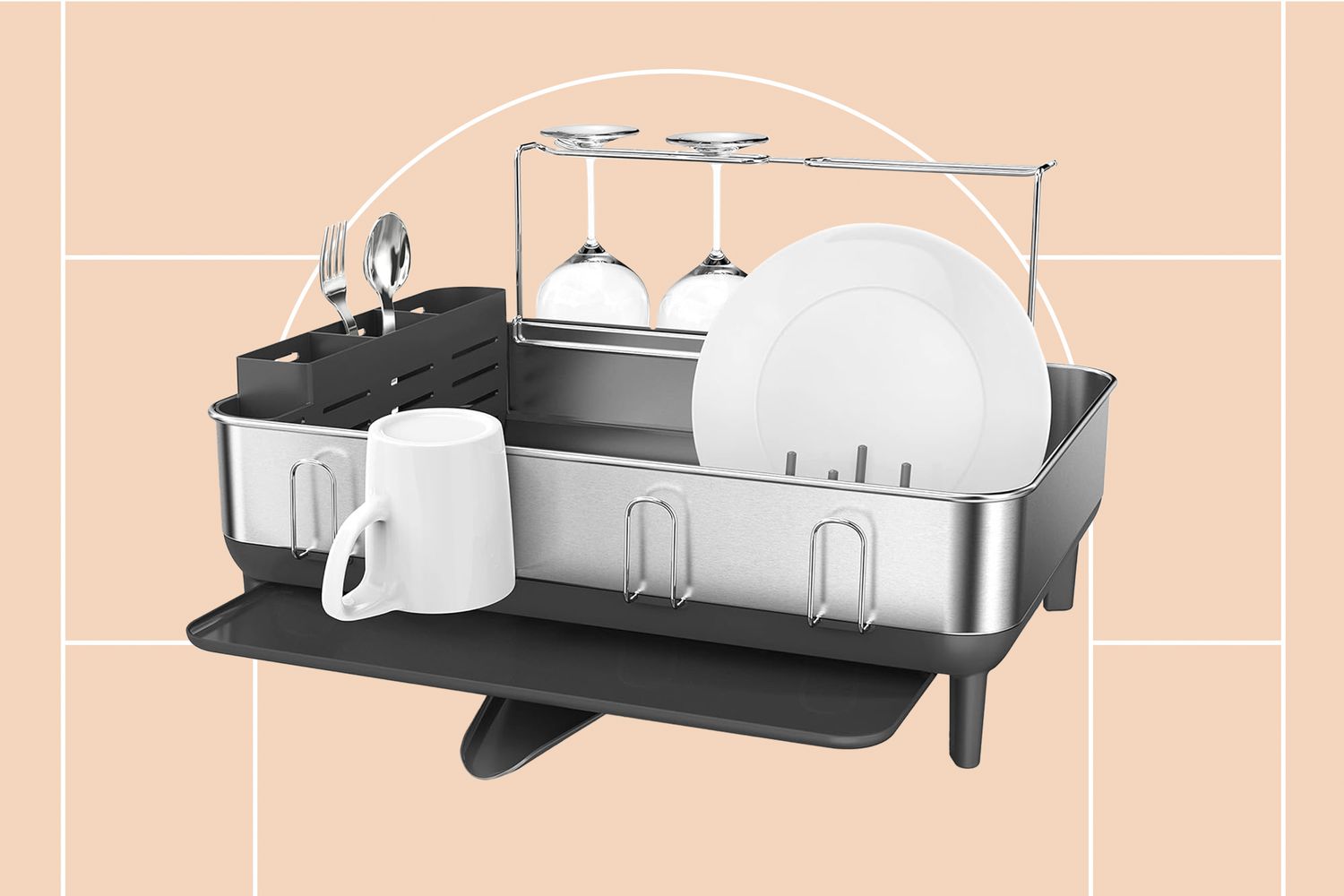

Not all dishes are created equal, and some require specialized care. You’ll find commercial dish drying racks specifically designed for delicate glassware, ensuring proper drainage and preventing chips or breakage. There are also robust racks for cafeteria trays, large pots, and unwieldy pans, often with wider slots or peg-style configurations. These specialty racks ensure every item, no matter its shape or size, gets the optimal airflow it needs to dry completely and hygienically.

Tiered and Modular Systems: Maximizing Vertical Space

When horizontal space is at a premium, tiered and modular commercial dish drying rack systems are a game-changer. These multi-level units allow you to dry a significant volume of items in a compact footprint. Many systems are highly customizable, featuring adjustable shelves, various inserts, and accessory hooks for ladles, tongs, and cutting boards. This modularity means you can configure the rack to suit your precise inventory, adapting it as your kitchen’s needs evolve.

Materials Matter: Durability Meets Sanitation

The material of your commercial dish drying rack is paramount, directly influencing its durability, hygiene, and longevity in a demanding commercial environment.

Stainless Steel: The Commercial Standard

For good reason, stainless steel is a staple in commercial kitchens. A stainless steel commercial dish drying rack offers exceptional durability, corrosion resistance, and is inherently hygienic. It can withstand constant exposure to water, harsh detergents, and heavy loads without rusting or warping, making it a reliable choice for the framework and core components. Its non-porous surface also makes it easy to clean and sanitize.

Polymer and Coated Metals: Lightweight, Corrosion-Resistant, Antimicrobial Options

Advanced polymers and epoxy-coated metals provide excellent alternatives, often offering a lighter weight without compromising on performance. Polymer racks are corrosion-resistant and often feature antimicrobial protection, actively inhibiting the growth of bacteria and mold. Coated steel racks provide a robust, rust-resistant surface, often with a powder-coated finish for added durability. These materials are frequently used for removable mats, drip trays, and rack components that come into direct contact with water, simplifying cleaning.

“The best materials for a commercial dish drying rack blend robust durability with superior sanitation properties,” explains Michael Lee, a product engineer specializing in foodservice equipment. “Corrosion resistance isn’t a luxury; it’s a necessity in a damp, high-usage environment.”

Key Features to Look for in a Commercial Dish Drying Rack

Choosing the perfect commercial dish drying rack involves more than just picking a type or material. It’s about understanding the features that will truly benefit your operation.

Capacity and Size: Matching Your Volume

Consider the volume of dishes you process daily and the types of items. Dish racks typically come in full-size (around 20″ x 20″) or half-size (around 20″ x 10″) to fit commercial dishwashers and optimize workflow. Ensure the rack’s overall dimensions fit comfortably within your available space without obstructing pathways or other equipment. An undersized rack leads to bottlenecks, while an oversized one wastes valuable kitchen real estate.

Airflow and Drainage: The Core of Efficient Drying

The fundamental purpose of a dish drying rack is to promote drying. Look for designs that maximize air circulation around each item. Open wire designs or racks with ample spacing between pegs are ideal. Integrated drip trays are essential to collect excess water, channeling it away, often with a swivel spout, directly into a sink to prevent pooling and maintain a dry, safe floor. Many removable components are also designed to be dishwasher safe for thorough cleaning.

Ease of Cleaning and Maintenance: Keeping Things Sanitary

In a commercial kitchen, sanitation is paramount. Choose a commercial dish drying rack with smooth surfaces, minimal nooks, and crannies, and removable components that are easy to clean by hand or in a dishwasher. Antimicrobial coatings can offer an extra layer of protection against bacterial growth, simplifying daily maintenance and ensuring long-term hygiene.

NSF Certification: Non-Negotiable for Commercial Settings

For any equipment used in food service, NSF certification is a strong indicator of compliance with public health and sanitation standards. An NSF-listed commercial dish drying rack means it meets rigorous requirements for material safety, design, construction, and performance, ensuring it’s suitable for a professional kitchen environment. Always look for this certification to ensure you’re investing in a product that upholds the highest hygiene standards. Many local health codes often require air-drying after sanitization, making these racks indispensable.

Customization and Accessories: Tailoring to Your Needs

Some of the best commercial dish drying rack systems offer modularity. Look for options that allow you to add or adjust shelves, incorporate specialized holders for flatware or cutting boards, or attach hooks for hanging smaller utensils. This flexibility ensures your drying solution can adapt to changes in your menu, equipment, or workflow.

Tips for Maximizing Your Commercial Dish Drying Rack’s Potential

Getting the most out of your commercial dish drying rack isn’t rocket science, but a few smart practices can make a big difference in efficiency and longevity.

Proper Loading Techniques

Avoid overcrowding your rack. While tempting to cram as many dishes as possible, it hinders airflow and slows drying. Load items with ample space between them, ensuring water can drip away freely and air can circulate. Stand plates upright, invert glasses and bowls, and utilize specialized sections for flatware and odd-shaped items. This promotes faster drying and prevents unpleasant odors.

Regular Cleaning Routines

Even with antimicrobial properties, regular cleaning is crucial. Disassemble removable parts like drip trays and mats, washing them thoroughly with hot, soapy water or running them through your commercial dishwasher. Wipe down the frame and fixed components daily to prevent mineral buildup and ensure continued hygiene. Consistency is key to maintaining a pristine drying station.

Strategic Placement for Optimal Drying

Position your commercial dish drying rack in an area with good air circulation. If it’s near a window or an exhaust fan (without risking contamination), even better. Avoid placing it in humid, stagnant corners where drying times will be prolonged, and bacterial growth is more likely. Mobile racks offer the advantage of repositioning them for optimal conditions.

The Bottom Line: Investing in a Seamless Kitchen Workflow

In the demanding world of commercial food service, every piece of equipment plays a role in your overall success. A commercial dish drying rack, while seemingly simple, is a vital component that significantly impacts your kitchen’s hygiene, efficiency, and organization. Investing in a high-quality, NSF-certified rack that matches your specific operational needs will not only streamline your dishwashing process but also contribute to a safer, more productive, and more professional kitchen environment. It’s an investment that pays dividends in both operational ease and peace of mind.

Frequently Asked Questions About Commercial Dish Drying Racks

What is the standard size for a commercial dish drying rack?

Commercial dish drying racks typically come in standard full-size (approximately 20 inches by 20 inches) or half-size (approximately 20 inches by 10 inches) dimensions, designed to fit commercial dishwashers and maximize space efficiency.

How often should a commercial dish drying rack be cleaned?

For optimal hygiene, a commercial dish drying rack should be cleaned daily. Removable components like drip trays and mats should be washed thoroughly, and the main frame wiped down to prevent water spots and bacterial buildup.

Are all commercial dish drying racks NSF certified?

While many reputable commercial dish drying racks are NSF certified, it’s not universally true for all products on the market. Always verify that a rack has NSF certification to ensure it meets public health and sanitation standards for commercial use.

Can commercial dish drying racks be used for all types of dishes?

Yes, most commercial dish drying racks are designed to accommodate a wide range of items, including plates, bowls, glassware, cutlery, pots, pans, and trays. Many systems also offer specialized inserts or configurations for specific types of wares.

What are the benefits of a mobile commercial dish drying rack?

Mobile commercial dish drying racks offer exceptional flexibility, allowing staff to easily move the drying station to different areas of the kitchen as needed. This improves workflow, adapts to varying demands, and provides greater versatility in space management.

How do commercial racks prevent bacteria growth?

Commercial dish drying racks prevent bacteria growth primarily by promoting efficient airflow, which speeds up drying and prevents moist environments where bacteria thrive. Many also feature antimicrobial coatings and are made from non-porous, easy-to-clean materials that deter microbial buildup.